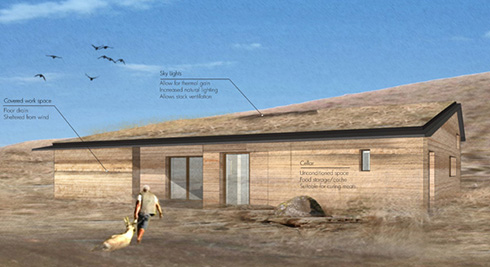

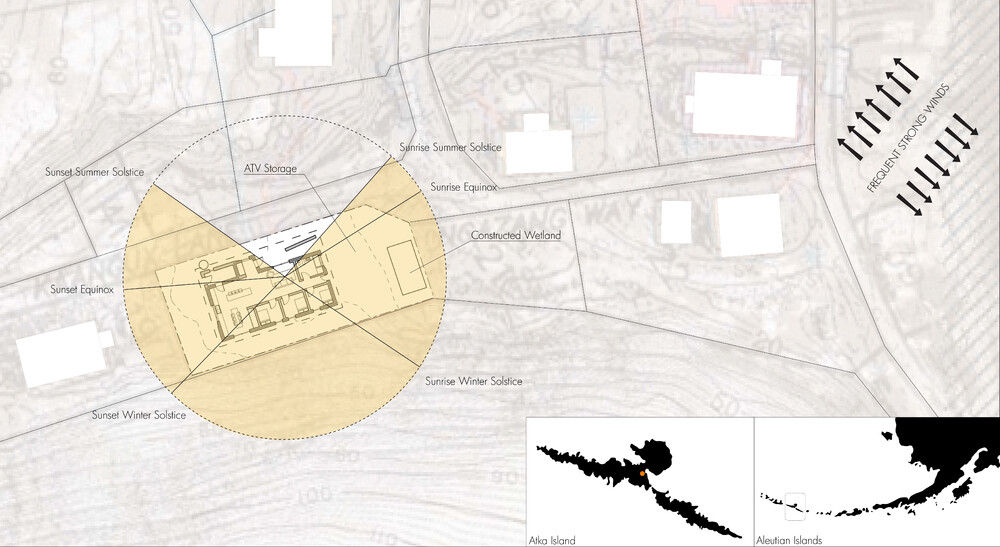

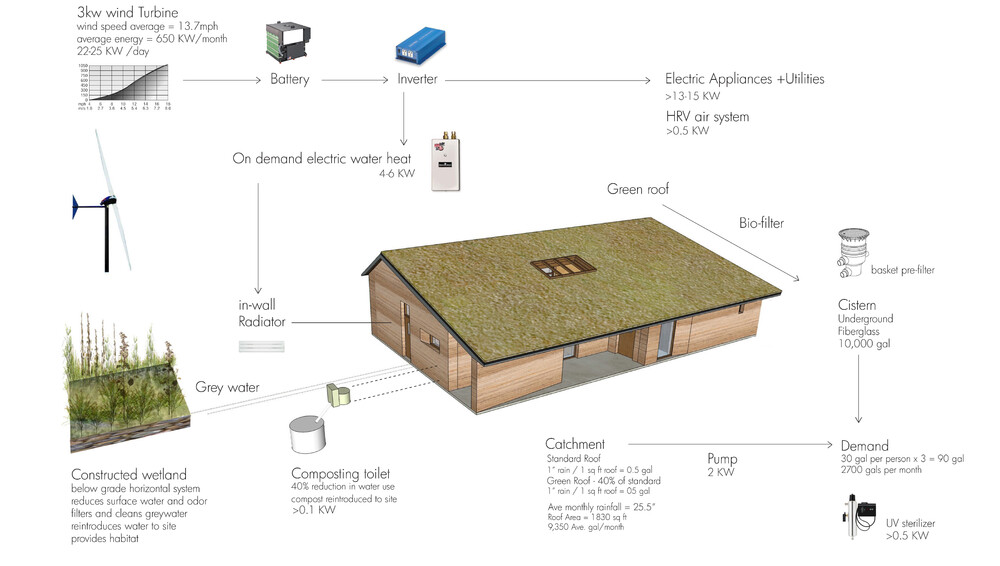

Reflecting the regional ecology and the building vernacular heritage, the Aleutian Earth House appears to have been drawn from the earth upon which it stands. In response to the wind, the form is compact with modest overhangs. The carved entry provides a sheltered vestibule, indicative of the indigenous Barbara dwellings. A sod roof blends the residence with the surrounding hillsides, offers habitat for migratory birds, and provides insulation. The thick rammed earth’s organic lift lines express the characteristics of Atka’s subsoil and blend beautifully with the landscape. The design is guided by the necessity to shelter, sustain, and inspire for generations. . The green roof provides multiple environmental benefits which extend beyond the structure and site; it will remove particulates from the atmosphere and act as a bio filter for the rainwater, before storage for uses on the site. The native plants will provide habitat that offsets the building footprint.

Atka’s soils that are appropriate for rammed earth are also a suitable material for the footings and interior floor slab. It is common for rammed earth contractors to use the rammed earth mix designs for poured elements such as the wall cap, window sills, and lintels over openings. These elements are structural; with appropriate tests a mix design for footings is also possible. This soil cement would also benefit from the substitution of recycled slag for 50-60% of the cement content, with the same benefits to the strength and durability of the material as well as the reduced carbon footprint. This material will be durable with a very long lifecycle and can be recycled.

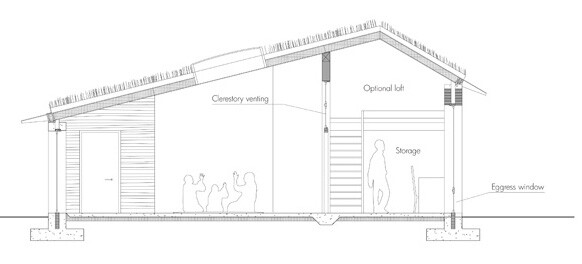

Water is an abundant resource on Atka. Filtering through the green roof vegetation, rain water is collected for non-potable use; primarily for the exterior needs that accompany subsistence living. Due to the consistent rains of the island and a productive water table, a well provides potable water for the residence. The well maintains the ecological flow of water by limiting the amount of rainwater stored on site and compensates for the reduced runoff from a green roof. This principle is carried through the structure by the incorporation of a composting toilet that eliminates black water and significantly decreases water demand by eliminating its use in the waste stream. Grey water from sinks, showers and laundry are circulated through a subsurface horizontal wetland that cleans and reintroduces water to the site, as well as provides additional on-site habitat.

The residence is designed to incorporate multiple energy systems. One scenario is that the south shed roof provides space for a photovoltaic (PV) array sized to provide in excess of 640 KW/month. The disadvantage to utilizing PV for the energy needs is the necessity to size the system for the winter months when daylight is scarce; in the summer there is an excess of power that cannot be utilized without a grid. A net-zero solar array in Atka is possible, yet we feel it is not practical given the budget, but we have designed the Aleutian Earth House to incorporate solar for a hybrid system.

The Aleutian Earth House takes a step towards energy neutrality by utilizing the prevalent wind energy afforded on the site to provide the average household energy consumption of 640 kW/month. A 3kW wind turbine designed to generate 650-700 kW/month in average wind conditions specific to Atka (13-14 mph average wind speed). However, as there is already a significant investment in hydro power, it makes sense to utilize this source as well. We believe that through community planning and investing, wind turbines could be clustered to optimize energy production, limit the number of turbines to mitigate danger to migratory birds, and take advantage of locations ideal for wind power generation. A larger scale would afford more efficient power production for less cost than an individualized

The inclusion of rigid insulation in the core of the wall will permit the rammed earth to outperform other wall systems in a heating climate such as Atka’s. The insulation is rammed in the core of the wall, where it is protected from pests and any environmental degradation. This provides a continuous thermal break between the interior and exterior wythes of rammed earth. This combination of materials will provide thermal performance that neither material could provide alone, and is not reflected in a comparison of R-values, as the 90 tons of interior rammed earth will function as an enormous heat sink. This flywheel effect results in an environment that is uniformly warm throughout the structure and has a performance rating comparable to an R-50 stick frame wall. It is also effective at maintaining a constant humidity that is ideal for humans and lower than mold can tolerate. The walls require no finishes after being rammed as they are naturally beautiful; they are unique, with horizontal lift lines that reflect the layers of earth placed in the forms. The walls resemble fine sandstone and the minutely faceted surface refracts sound in a diffuse manner (unlike concrete) that creates superior interior acoustics. The house will be solid and quiet.

SIP panels are an appropriate choice for the roof. They are relatively lightweight and easily transported. Their modular nature will permit rapid installation on site. The EPS provides a good balance between cost and R- value. They can be assembled using FSC certified plywood. By integrating FSC certified TGI joists into the panel seams the SIPs can support a green roof that will further insulate above the panels. Serious Windows™ will provide the best solution for glazing given the exposure to weather. The windows are energy efficient (U-factor .11-.15) and are constructed with fiberglass frames that will ensure low maintenance exterior for many years.

Bio foam is a type of non-toxic polyurethane rigid foam developed from plant polyols unlike standard polyurethane that is derived from petro-chemicals. Bio foam is developed with plant-based non-toxic MDI (methylene-based isocyanate) and is completely recyclable and manufactured from sustainable resources. There are no toxic chemicals involved in the production of Bio foam and the USDA has granted the product with a 46% bio rating. The harmful chemical MDA, a building block in pMDI, is found in traditional polyurethane, is not present in Bio foam. An additional 10% of the product is sourced from recycled content. With a performance and durability comparable to XPS and Polyisocyanurate, Bio foam currently offers the best alternative to traditional rigid foam insulation and we feel it should be distinguished from the Red Listed Polyurethane foams.